Any Battery. Anywhere.

Ecobat Battery manages the procurement and sale of energy storage solutions. We supply batteries for a wide range of uses, including automotive, commercial vehicle, marine and leisure, motorcycle and industrial applications. We are the sole European license holder and distributor of Lucas and Rolls batteries and a key distributor for Exide, Varta, US Battery, Optima, Sonnenschein, Tab and more. In addition to our vast portfolio of products, we offer various services to our industrial customers, including battery maintenance contracts, installation, and repair.

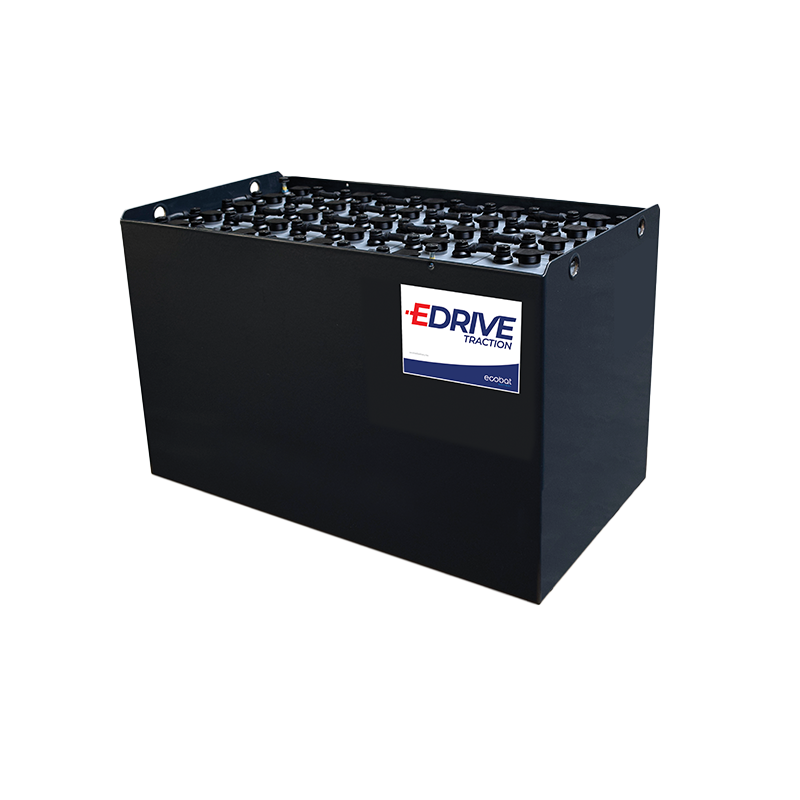

Technical Information

As experts in battery technology - ranging from the smallest consumer batteries to batteries for complex industrial installations, Ecobat Battery knows its stuff! We partner with the leading global battery manufacturers to bring you the best-in-class energy solutions.

Our Locations

Ecobat Battery are physically present in seven European countries with export opportunities from most branches. We have exclusive distribution deals with many brands and are also able to offer you the benefit of our pan-European purchasing power.

FIND YOUR NEAREST LOCATION

Engage With Us

Powered by Juicer.io